The blow up ratio is one of the most important yet misunderstood parameters in blown film extrusion. Whether you are a beginner learning the basics or a professional optimizing production, understanding blow up ratio can significantly improve film quality, strength balance, and process stability. In simple terms, blow up ratio controls how much the molten plastic tube is expanded during extrusion, and this expansion directly affects the film’s mechanical and optical properties.

In the first moments after the polymer exits the die, it is stretched and inflated into a bubble. The degree of this inflation defines the blow up ratio, commonly referred to as BUR. Even small adjustments to blow up ratio can change tear resistance, tensile strength, haze, and bubble stability, which is why BUR is considered a core process variable in blown film manufacturing.

What Is Blow Up Ratio?

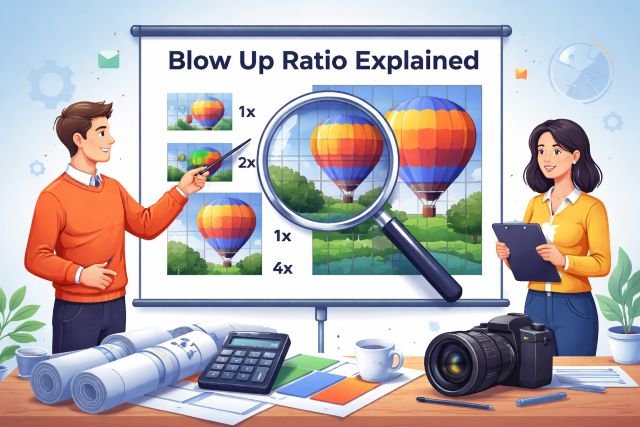

The blow up ratio is defined as the ratio between the diameter of the inflated bubble and the diameter of the die from which the melt exits. It describes how much the film is stretched in the transverse direction during the blown film process. According to industry references, blow up ratio is calculated by dividing the bubble diameter by the die diameter, making it a straightforward but powerful measurement.

For example, if a die has a diameter of 200 millimeters and the stabilized bubble diameter measures 500 millimeters, the blow up ratio is 2.5. This single number provides insight into how the polymer chains are oriented across the film width.

Why Blow Up Ratio Is So Important in Blown Film Extrusion

Blown film production relies on controlled stretching of polymer melt in two directions. Stretching along the machine direction is influenced by haul-off speed, while stretching across the transverse direction is mainly controlled by blow up ratio. Increasing the blow up ratio increases transverse direction orientation, which directly impacts the balance between MD and TD strength.

This balance is critical because films that are too strong in one direction and weak in the other can fail during converting or end use. A well-optimized blow up ratio helps achieve uniform mechanical performance, better tear control, and improved durability.

How to Calculate Blow Up Ratio Correctly

Calculating blow up ratio requires accurate measurement of the bubble diameter. The most direct method is to measure the diameter of the stable bubble and divide it by the die diameter. In cases where only the bubble circumference is available, the diameter can be calculated by dividing the circumference by pi, and then dividing the result by the die diameter.

Consistency in measurement location is critical. Measuring the bubble at different heights or during unstable conditions can lead to misleading blow up ratio values and incorrect process adjustments.

Typical Blow Up Ratio Ranges

In most commercial blown film operations, the blow up ratio commonly falls between 2:1 and 4:1, depending on resin type, film thickness, cooling efficiency, and end-use requirements. While these ranges are common, there is no universal “best” blow up ratio. Each product requires its own optimized balance based on performance needs and line capability.

Technical data for polyethylene films often reference mid-range blow up ratios around 2.5, showing that moderate BUR values are widely used for balanced film properties.

How Blow Up Ratio Affects Film Properties

Blow up ratio has a direct influence on mechanical strength, tear behavior, thickness distribution, and optical properties. As blow up ratio increases, transverse direction strength typically increases while machine direction strength becomes relatively lower. This change is beneficial when TD tear resistance is required but can cause issues if MD strength drops too far.

Thickness uniformity is also affected by blow up ratio. Higher BUR values increase sensitivity to cooling inconsistencies and die variations, which may result in gauge bands or unstable bubbles if the cooling system is not capable of supporting the added expansion.

Optical properties such as haze and clarity are indirectly influenced by blow up ratio. Research on polyethylene blown films shows that surface roughness is a dominant contributor to haze, and processing conditions that affect surface formation, including BUR and cooling, can impact clarity.

Relationship Between Blow Up Ratio and Other Process Variables

Blow up ratio does not operate independently. It works in combination with draw ratio, frost line height, melt temperature, and cooling capacity. Increasing blow up ratio without adjusting other parameters can lead to bubble instability or inconsistent film properties.

The frost line height, where the polymer transitions from molten to solid, plays a critical role in orientation development. Industry guides note that frost line position relative to die diameter is an important consideration when optimizing blow up ratio and overall film quality.

Choosing the Right Blow Up Ratio for Your Application

Selecting the correct blow up ratio starts with understanding the end-use requirements of the film. Packaging films typically require balanced MD and TD strength, while agricultural and industrial films often prioritize puncture resistance and tear performance. Stretch films and high-clarity applications require careful control of blow up ratio along with cooling and surface quality to achieve optimal results.

Rather than relying on a fixed number, experienced processors adjust blow up ratio incrementally and evaluate its effect on mechanical testing, bubble stability, and converting performance.

Common Blow Up Ratio Problems and Solutions

When blow up ratio is increased too aggressively, bubble instability is one of the first problems to appear. This often indicates that cooling capacity or air ring uniformity is insufficient to support the expanded bubble. Reducing BUR slightly or improving cooling balance usually restores stability.

If transverse direction strength is too low, increasing blow up ratio is a common corrective action because it increases TD orientation. If clarity worsens after a BUR adjustment, it is important to evaluate cooling uniformity and surface roughness rather than assuming blow up ratio is the only cause.

Frequently Asked Questions About Blow Up Ratio

Blow up ratio means how much the blown film bubble expands compared to the die diameter, and it defines the level of transverse stretching in the process.

A higher blow up ratio is not always better because excessive expansion can reduce stability and create thickness variations if cooling and control systems are limited.

Most blown film lines operate with blow up ratios between 2 and 4, but the optimal value depends on resin, equipment, and product requirements.

Conclusion

The blow up ratio is a simple calculation with a powerful impact on blown film quality. By controlling how much the bubble expands, manufacturers influence transverse orientation, strength balance, clarity, and process stability. For beginners, understanding and measuring blow up ratio consistently is the first step toward better film control. For professionals, fine-tuning blow up ratio in coordination with draw ratio and cooling conditions is one of the most effective ways to optimize performance and reduce defects.

When used thoughtfully, blow up ratio becomes more than a setting. It becomes a strategic tool for producing consistent, high-quality blown film that meets both processing and customer demands.

Leave a comment