What Is Marlex and Why It Matters

In the world of advanced materials, Marlex stands out as a true game-changer. Developed in the mid-20th century, this polyolefin polymer has redefined manufacturing standards across industries — from healthcare and packaging to automotive and construction.

But what makes Marlex so revolutionary? The answer lies in its unique molecular structure, exceptional strength-to-weight ratio, and resistance to heat and chemicals. These properties allow manufacturers to design lighter, stronger, and more sustainable products without compromising performance.

In this article, we’ll explore the science, applications, and innovations behind Marlex — and why it continues to lead the polymer revolution in modern industry.

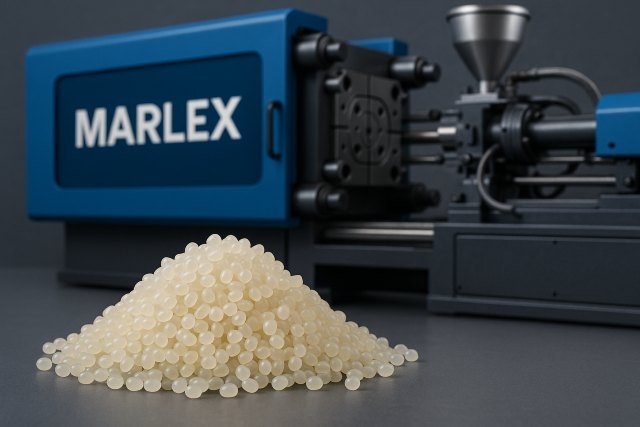

What Is Marlex? A Quick Overview

Marlex is a high-density polyethylene (HDPE) polymer first commercialized by Phillips Petroleum Company (now part of Chevron Phillips Chemical). It’s produced through a catalytic polymerization process using ethylene monomers, resulting in a material that is both rigid and lightweight.

Key Properties of Marlex

| Property | Description |

|---|---|

| Density | ~0.94–0.97 g/cm³ (high-density) |

| Melting Point | ~130–137°C |

| Chemical Resistance | Excellent against acids, bases, and solvents |

| Impact Strength | High durability even under stress |

| Environmental Stability | UV and moisture resistant |

These characteristics make Marlex HDPE ideal for applications requiring durability, reliability, and long service life.

The Origins of Marlex: A Historical Innovation

The invention of Marlex is rooted in 1950s polymer research. Scientists Robert Banks and J. Paul Hogan at Phillips Petroleum developed the Phillips catalyst, which enabled the creation of Marlex with a perfectly balanced crystalline structure.

Interestingly, Marlex gained fame when it became the primary material for the Hula Hoop, a global sensation in the late 1950s. Beyond toys, its applications soon expanded to industrial components, medical devices, and packaging materials.

How Marlex Is Changing Modern Manufacturing

1. Lightweight Automotive Components

Modern car manufacturers use Marlex polymers to reduce vehicle weight without sacrificing structural integrity.

- Applications: Fuel tanks, bumpers, and air ducts.

- Benefits: Improved fuel efficiency, corrosion resistance, and recyclability.

2. Medical and Healthcare Equipment

Marlex’s biocompatibility has made it a preferred material in medical implants and surgical instruments.

- Example: The Marlex mesh, used in hernia repair surgeries, provides superior tissue integration and durability.

3. Sustainable Packaging Solutions

As global industries move toward eco-friendly materials, Marlex offers recyclability and low carbon footprint advantages.

- Used in: Bottles, caps, containers, and flexible packaging films.

- Key advantage: Reduces waste while maintaining barrier strength.

4. Industrial and Construction Applications

In construction, Marlex pipes and fittings offer exceptional strength, temperature tolerance, and chemical resistance.

- Example: Municipal water and gas pipelines using Marlex HDPE are corrosion-free and last decades.

Marlex vs. Traditional Polymers: A Comparison

| Feature | Marlex (HDPE) | PVC | Polypropylene (PP) |

|---|---|---|---|

| Density | High | Medium | Low |

| Flexibility | Moderate | Rigid | Flexible |

| Temperature Resistance | Excellent | Moderate | Good |

| Chemical Resistance | Superior | Good | Moderate |

| Sustainability | Highly recyclable | Limited | Recyclable |

| Cost Efficiency | High | Medium | High |

Marlex’s balance of strength, cost, and eco-performance makes it the go-to choice for modern engineering and consumer products.

Why Manufacturers Prefer Marlex

1. Durability Meets Sustainability

Unlike many polymers, Marlex doesn’t degrade easily under UV or environmental exposure, making it ideal for long-term outdoor use.

2. Cost-Effective Production

Marlex is easy to mold, extrude, and process, reducing manufacturing time and energy costs.

3. Recyclability and Circular Economy

Being part of the polyolefin family, Marlex is 100% recyclable and compatible with circular production models — supporting global sustainability goals.

FAQs About Marlex

Q1: Is Marlex environmentally friendly?

Yes. Marlex is recyclable and can be reused in multiple production cycles without losing structural integrity.

Q2: What industries use Marlex most?

Automotive, medical, packaging, and construction sectors are the top users.

Q3: How is Marlex different from regular polyethylene?

Marlex is a high-density polyethylene (HDPE) variant—denser, more rigid, and more resistant to chemicals and temperature variations.

Q4: Can Marlex be used for 3D printing?

Yes. Advanced HDPE filaments derived from Marlex are increasingly used in industrial 3D printing for lightweight, durable parts.

Future Innovations: The Next Generation of Marlex Polymers

Chevron Phillips Chemical continues to expand Marlex’s potential through copolymer innovations, bio-based feedstocks, and enhanced recyclability programs.

Research into Marlex Anew™, for example, focuses on circular polymers made from recycled feedstock—marking a major step toward zero-waste manufacturing.

Conclusion: Marlex — Pioneering the Future of Manufacturing

From its humble origins to its pivotal role in global industries, Marlex has truly earned its place as a revolutionary polymer. Its combination of strength, versatility, sustainability, and cost efficiency continues to transform how we design and build the products of tomorrow.

As industries demand smarter and greener materials, Marlex remains at the forefront of modern manufacturing innovation — proving that even a small molecule can make a massive difference.

Leave a comment